Engineered flooring is currently one of the most popular flooring options on the market, widely favored by consumers for its versatility and excellent cost-performance ratio. However, before making a purchase, it's important to ensure that it truly meets your home's specific needs. Below, we’ve compiled 12 key questions about engineered wood flooring—this guide will help you make an informed decision.

- 1. What is engineered wood flooring?

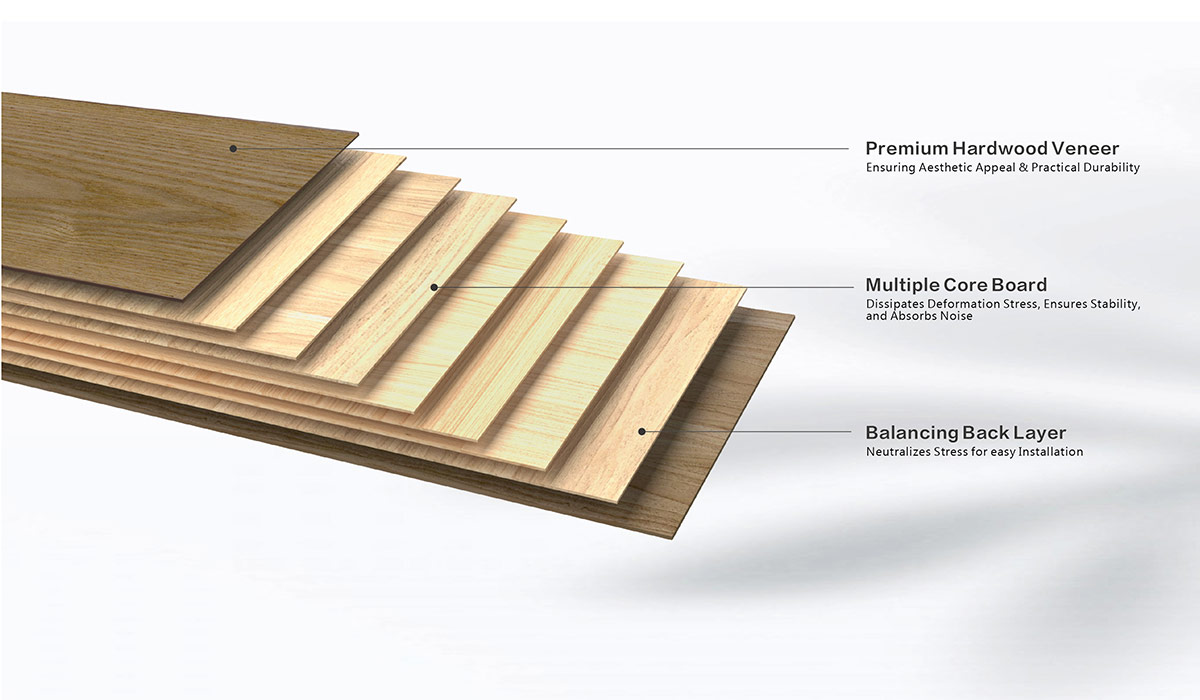

Engineered wood flooring consists of multiple layers: a top layer of real hardwood (veneer), a core layer of plywood or high-density fiberboard (HDF), and a stabilizing bottom layer. This construction makes it more stable than solid hardwood, reducing expansion and contraction due to humidity changes.

2. How does engineered wood differ from solid hardwood and laminate flooring?

· Solid Hardwood: Made entirely of natural wood; prone to warping in high-moisture environments.

· Engineered Wood: More stable due to its layered construction; can be installed in basements and over radiant heating.

· Laminate: Has a photographic wood layer (not real wood) topped with a wear layer; less authentic in appearance.

3. Can engineered wood flooring be refinished?

Yes, but the number of refinishes depends on the thickness of the top veneer (typically 2mm–6mm). Thicker veneers (4mm+) allow for 2–3 refinishes, while thinner ones (2mm) may only permit one light sanding.

4. Is engineered wood flooring waterproof?

No, but it is more moisture-resistant than solid hardwood. Some brands offer water-resistant finishes or treatments, but prolonged exposure to moisture can still cause damage.

5. Where can engineered wood flooring be installed?

It’s suitable for most areas, including living rooms, bedrooms, and kitchens. It can also be installed over concrete subfloors (with a moisture barrier) and in basements (if properly acclimated). However, bathrooms and laundry rooms are not recommended due to high humidity.

6. What are the best finishes for durability?

· UV-cured aluminum oxide: Most scratch-resistant.

· Oil-based finishes: Natural look but require more maintenance.

· Matte vs. Gloss: Matte hides scratches better; gloss is more formal but shows wear.

7. How do I maintain engineered wood floors?

· Sweep/vacuum regularly to prevent grit scratches.

· Use a damp (not wet) mop with a pH-neutral cleaner.

· Avoid steam mops, wax, and harsh chemicals.

8. Can engineered wood be installed over radiant heating?

Yes, but check the manufacturer’s guidelines. The flooring must be rated for thermal stability, and the heating system should maintain a consistent temperature.

9. What is the lifespan of engineered wood flooring?

With proper care, it can last 20–30 years. Thicker wear layers and high-quality cores extend longevity.

10. How do I choose the right grade and color?

· Grades: Select (few knots, uniform color), Natural (some variation), Rustic (more knots and character).

· Colors: Lighter shades (oak, maple) hide dust; darker tones (walnut, ebony) show scratches more but offer elegance.

11. Should I choose click-lock or glue-down installation?

· Click-lock (floating): Easier DIY installation, faster, and allows for expansion.

· Glue-down/Nail-down: More stable, better for high-traffic areas, but requires professional help.

12. How long does acclimation take before installation?

Typically 48–72 hours in the room where it will be installed to adjust to humidity and temperature.

By understanding these key aspects, consumers can make informed decisions when purchasing and maintaining engineered wood flooring. Always check manufacturer warranties and installation guidelines for specific product recommendations.